Wages in the Nineteenth Century

|

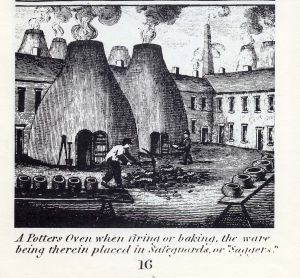

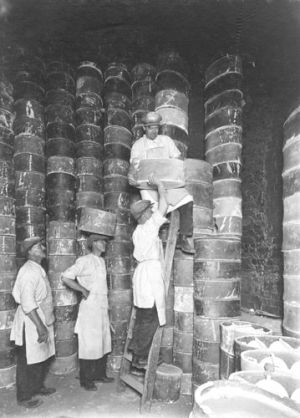

That year Spode was particularly interested in other firms’ production methods, styles and workers. Workers such as Boot Astbury engaged to throw pieces for Spode at ten pence per score “to calculate according to Minton’s method.” John Burne, another turner, engaged to turn for Spode by the piece “to be regulated according to Smith & Jarvis prices.” William Lewis, who made molds and squeezedhollow-wares was paid by the week but if work was slower, he would work “by the piece to have Minton’s prices.” Spode was keenly aware of his competition as the same Lewis received “1 [shilling] in hand to make it up at Christmas, as much as Minton & Co give their squeezers.” He notes that “M & Co give for printing Sily(sic) teaware 4 d per doz to printers and 3d to the transferrers.” Spode examined every portion of his production and compared it with his competitors. Everything from his slip makers to retail prices was measured against their rates. Sitting up with the ovensovernight meant extra pay, usually a few shillings, but it occasionally required special compensation. Joseph Tittensor minded the biscuit oven for sixteen shillings per week, with six pence “for beer each oven and a pint of ale when done firing.” Some forty years later, evidence collected by Samuel Scrivenincluded information from workers on the Spode factory, then owned by Copeland & Garrett. Dippers wages averaged thirty shillings per week, but they were actually paid by the piece. Charles Barker, the dipper interviewed, noted that they received higher wages “because the work is considered more pernicious than any other upon the bank.” George Bell, a printer, received approximately twenty-five shillings a week. Painters received considerably less. Girls started at a shilling a week, boys at two, and received regular rises until they began piece work—usually by their fifth year in the industry. Ware sorters received three shillings nine pence per week. China pressers could receive between fifteen and sixteen shillings per week while throwers working on an engine-turned throwing wheel only two shillings three pence. Although no one interviewed oven or kiln supervisors at the Spode/Copeland-Garrett factory, at the nearby works of Minton & Boyle, the man in charge of the enamel kilns was paid one pound, one shilling per week. |

|

It was not unusual in the nineteenth century for workers to be paid

It was not unusual in the nineteenth century for workers to be paid